Catalytic HCl oxidation reaction: Stabilizing efect of Zr-doping on CeO2 nano-rods

Published:

Highlights

- Mixed Ce1-xZrxO2 nano-rods are active in the Deacon process at 430 °C.

- Chlorine is incorporated in the surface-near region of Ce1-xZrxO2 nano-rods: active phase.

- The stability of Ce1-xZrxO2 nano-rods depends strongly on the Zr-concentration.

- Thermodynamic modelling of Zr-induced stabilization of Ce1-xZrxO2 nano-rods.

Abstract

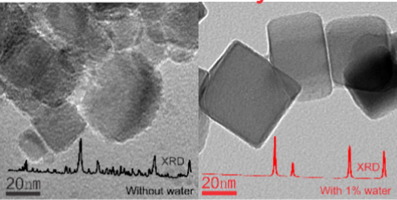

Mixed Ce1-xZrxO2 nano-rod particles with varying Zr doping levels of up to 20% were exposed to Deacon reaction mixtures with high HCl concentration at a reaction temperature of 430 °C. The mixed Ce1-xZrxO2 nano-rod samples were characterized before and after Deacon reaction by x-ray diffraction (XRD), transmission electron microscopy (TEM), and x-ray photoelectron spectroscopy (XPS). Pure CeO2 nano-rods are shown to suffer from bulk-chlorination of the catalyst (CeCl3x6H2O) for reaction mixtures HCl:O2 > 2 that is accompanied by dramatic activity losses. For a reaction mixture of HCl:O2 = 2.5:1, already 5% Zr doping suffices to stabilize the structure Ce1-xZrxO2 nano-rods against bulk chlorination. Although ZrCl4 is volatile above 330 °C, we do not encounter discharge of Zr from the fixed bed flow reactor as long as severe bulk chlorination of the Ce1-xZrxO2 catalysts in the form of CeCl3 is not observed in XRD. With a simple quasi steady-state model we can corroborate the stabilizing effect of Zr assuming that ZrCl4 evaporation is limited by diffusion of Zr4+ in the ceria-zirconia subsurface. As qunatified with XPS the chlorine concentration of stable and active Ce1-xZrxO2 nano-rods with 5% Zr is too high to be solely ascribed to on-surface chlorine. The incorporation of Cl into the surface-near region is further supported by XPS experiments performed after oxygen plasma treatment. For even more harsh reaction conditions HCl:O2 = 3:1 none of the Ce1-xZrxO2 nano-rods was stable at 430 °C. However, an increase of the reaction temperature to 500 °C enables even pure CeO2 nano-rods to be stable under such harsh reaction conditions.

Links

C. Li, Y. Sun, F. Hess, I. Djerdj, J. Sann, P. Vöpel, P. Cop, Y. Guo, B.M. Smarsly, H. Over. Appl. Catal. B 239 (2018) 628-635. 10.1016/j.apcatb.2018.08.047